19. September 2025

100 per cent digital quality assurance

Two birds with one stone: quality control and defect management synergistically linked in an automated process.

Smooth interaction − checklist module & defect management

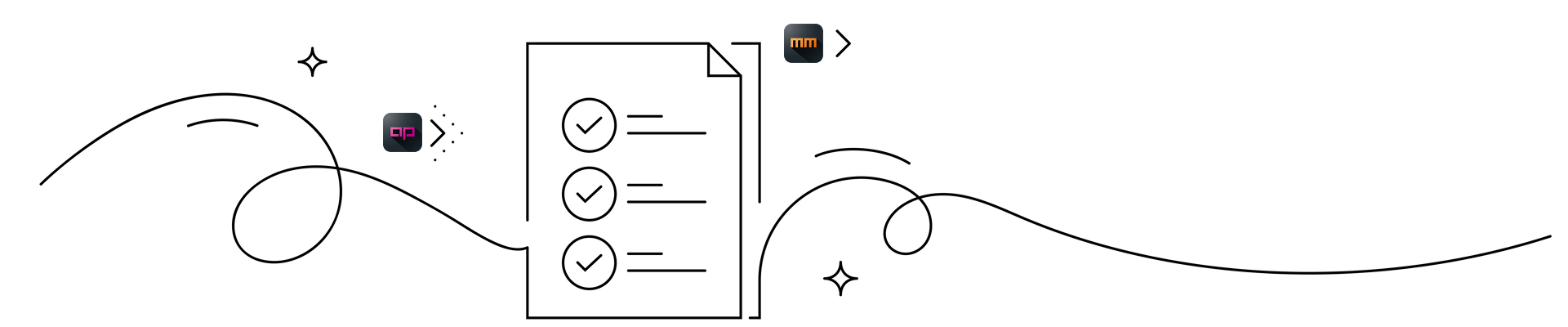

Wohnungsübergabeprotokoll, Inspektionscheckliste, Abnahmeprotokoll, Qualitätsprüfung, etc. – nutzen Sie unser Checklistenmodul mydocma AP in Kombination mit unserem Mängelmanagement mydocma MM und Sie profitieren Sie von einer schnellen, transparenten und medienbruchfreien Prozesskette bei der Mangelbearbeitung – 100 Prozent digital, maximal effizient, konsequent in der Qualitätssicherung.

End-to-end process chain in ironing management – from checklist entry to acceptance

1. Defect recording via mydocma AP checklist

The use of standardised checklists is essential for quality checks. The mydocma AP module systematically records all relevant data for defect processing in a digital checklist – such as defect description, photo, location data, defect type, attachments, etc. Individually definable visibility rules ensure that fields for recording defects are only displayed if the option ‘Defect present’ has been answered with ‘Yes’ in the checklist. This show/hide function makes the form particularly user-friendly, as only the content that is actually needed is displayed and the rest is hidden.

2. Automatic deficiency transfer

All defect content recorded in the AP checklist is automatically transferred directly to the defect management system via a reliable exchange format.

3. Defect handling via MM module

In the mydocma MM defect management module, automatically created defects can be processed immediately. It covers all relevant steps – such as VOB correspondence, defect-free notification by the trades via web link/QR code, deadlines/notification system, defect control via layouts, filters and defect pools, reporting via reports/lists/statistics or localisation in the BIM model.

Double the efficiency with half the effort

Overview of the advantages of combining the mydocma AP & MM modules

- Reduction in costs – reduced administrative effort

- Standardisation – predefined checklists and systematic process sequence

- Time savings – automated workflow and synchronisation

- Minimisation of errors – no manual transfer activities and precise room/plan location